- Register

- Log in

-

Shopping cart

(0)

You have no items in your shopping cart.

FIRST Components Academy | Winstar Moves Into Growing Life Sciences Industry

From Winstar News of December '24

Winstar Moves Into Growing Life Sciences Industry

Through our collaboration with Winstar, FIRST Components offers advanced solutions tailored to the life sciences sector. Winstar is actively expanding its capabilities to address this market, providing in-house expertise and one-stop-shop services specifically designed for life sciences device needs.

As part of this strategic initiative, Winstar is preparing to begin the ISO13485 certification process, targeting completion by Q4 2025. This milestone will demonstrate Winstar’s commitment to adhering to the strict regulatory standards required in the life sciences industry.

To support this development, Winstar is investing heavily in improving the reliability of its processes and enhancing the quality of its testing methods. With this commitment, customers of FIRST Components can have confidence in solutions that meet the high standards of the life sciences sector, delivered with excellence and reliability.

Committed to Helping You Excel

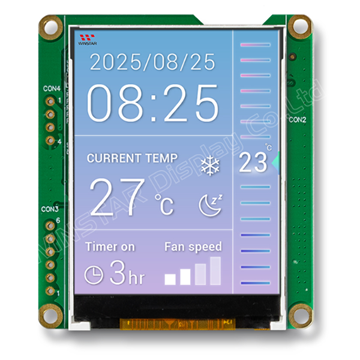

The design process for life sciences devices typically takes 2-3 years to complete. Once FDA certification is achieved, making changes becomes extremely costly. At the same time, consumer electronic displays are often discontinued within two years, creating a unique challenge for life sciences companies.

Through our collaboration with Winstar, a trusted and proven LCM (Liquid Crystal Module) manufacturer with over 26 years of expertise in low-volume, high-mix production, FIRST Components is equipped to support customers in overcoming these challenges.

Winstar is committed to providing continuous support for 5-7 years, offering consistent feedback and the stability essential for critical projects. Their world-class logistics and supply chain team works closely with customers to ensure a smooth design lockdown process.

To address the risk of obsolescence, Winstar delivers tailored solutions customized to each project. These exclusive designs are closely monitored, ensuring dedicated updates and specific support for every need.

Winstar provides a variety of product options:

- Long-lifetime displays: lasting 10+ years

- Customizable FPCs

- Custom cover glass solutions

- Dielectric materials to prevent EMI and ESD

Thanks to Winstar, FIRST Components can provide comprehensive and professional management of production needs, ensuring support at every stage of the process.

Case Study: Working With A Top 10 Medical Device Company

Recently, Winstar worked with a top 10 medical device company to develop a custom display featuring an integrated power button and a specific cutout on the cover lens.

To meet the stringent demands of the life sciences industry, Winstar utilized a special type of ink for the power button, rigorously tested to withstand hospital-grade cleaning processes. The ink successfully endured over 800 cleaning cycles with commonly used hospital wipes, such as Oxivir TB and H₂O₂. Additionally, the button material was designed to meet and exceed the high standards required for medical manufacturing.

Another critical challenge addressed was managing screen temperatures to prevent overheating. Winstar provided targeted solutions to reduce surface temperature, optimize the LCD, and configure the customer’s end product setup.

This project underscores Winstar’s ability to meet the unique needs of the life sciences sector, simplifying the production process for FIRST Components' customers.

Discover the Winstar Difference

Life sciences companies often face the challenge of sourcing separate suppliers for displays and buttons. With Winstar, FIRST Components can eliminate this complexity by offering integrated solutions that simplify product development and accelerate time to market.

With in-house expertise to manage both components and a continuous expansion of integration capabilities within ISO frameworks and medical industry standards, FIRST Components, in partnership with Winstar, stands out as a reliable LCM supplier for the life sciences market.

If you are looking for a manufacturing partner ready to invest in your success and deliver consistent results, FIRST Components, together with Winstar, is here to help. With this collaborative approach, customers can enjoy a seamless and worry-free experience, quickly getting their projects off the ground.