- Register

- Log in

-

Shopping cart

(0)

You have no items in your shopping cart.

FIRST Components Academy | Choosing Between Air and Optical Bonding Technologies

Air Bonding vs Optical Bonding: Choosing the Right Display Bonding Technology

When integrating TFT LCD or OLED displays into modern industrial and commercial devices, choosing the right bonding method is crucial to ensuring visual performance, durability, and cost efficiency. This article compares two mainstream bonding technologies—Air Bonding and Optical Bonding—helping developers, product designers, and project managers make informed decisions based on application needs.

What Is Display Bonding?

Display bonding refers to the technique used to attach the display panel (TFT LCD or OLED) to a cover glass or touch panel. The bonding method can significantly affect the display’s optical clarity, durability, and environmental performance.

Two major bonding types are:

• Air Bonding: The cover glass is bonded to the display with a thin air gap in between.

• Optical Bonding: A transparent optical adhesive (such as OCA or OCR) is used to eliminate the air gap and permanently fuse the layers.

Air Bonding

In Air Bonding, the cover lens or touch panel is attached around the edges of the display module, leaving a controlled air gap between the cover glass and the display panel. This method is also known as perimeter bonding.

Advantages:

• Lower material and production cost

• Easier rework or replacement of cover glass / touch panel

• Suitable for indoor or non-rugged applications

Disadvantages:

• Internal reflections due to air gap reduce clarity

• Poor sunlight readability

• More susceptible to moisture, dust, and condensation

• Lower resistance to vibration and impact

Optical Bonding

Optical Bonding employs an optically clear adhesive (e.g., OCA or OCR) to fill the gap between the cover lens and display panel, forming a solid laminated stack without air layers.

Advantages:

• Greatly reduced reflection and glare

• Enhanced sunlight readability and contrast

• Stronger structural integrity and impact resistance

• Better dust/moisture sealing, reducing risk of condensation

• Improved touch sensitivity and accuracy

Disadvantages:

• Higher material and process cost

• Requires precise alignment, controlled environment, and strict process control

• Rework or repair is more difficult once laminated

With optical bonding, the display and black silk print are seamlessly integrated, providing a more uniform and precise finish compared to air bonding.

Without an air gap, optical bonding ensures reduced reflection and improved light transmission, resulting in better brightness and visual performance.

Performance Comparison

The following table compares Air Bonding and Optical Bonding across key factors such as visual performance, structural strength, process complexity, and cost—providing a clear guide for selecting the appropriate bonding method.

| Category | Air Bonding | Optical Bonding |

|---|---|---|

| Bonding Method | Cover glass (CG) is attached to the LCM using double-sided adhesive tape around the bezel. | Optical adhesive is applied across the entire surface to fully bond the CG and LCM. |

| Process Complexity | Simple process; easy lamination. | More complex process; difficult lamination. |

| Optical Interference | Greater light refraction and reduced brightness/contrast due to internal reflections. | Minimal refraction; maintains brightness and contrast. |

| Visual Clarity | Lower image clarity and contrast. | High clarity and sharp contrast. |

| Structural Strength | Medium bonding strength. | High bonding strength. |

| Sealing & Protection | Moderate resistance to moisture and dust. | Excellent sealing and environmental protection. |

| Cost | Lower cost. | Higher cost. |

| First Pass Yield (FPY) | Higher FPY due to simpler process. | Slightly lower FPY due to process complexity. |

Application Guide

After understanding the structural and performance differences between Air Bonding and Optical Bonding, how should you decide which method is best for your product? Below is a concise guide to help you make the right choice based on your application environment and design priorities.

When to choose Air Bonding

Air Bonding is a practical choice for applications where ease of maintenance and cost effectiveness are key. It is especially suitable for:

• Indoor TFT LCD / OLED equipment

• Products requiring easy maintenance or field replacement

• Cost-sensitive devices without demanding optical or environmental requirements

When to choose Optical Bonding

Optical Bonding offers significant advantages in performance and durability for demanding environments. It is recommended for:

• Outdoor displays, kiosks, or devices requiring high sunlight readability

• Rugged environments subject to vibration, shock, or environmental stress

• Premium HMI interfaces demanding high clarity and reliability

• Medical, automotive, industrial applications requiring strong sealing and durability

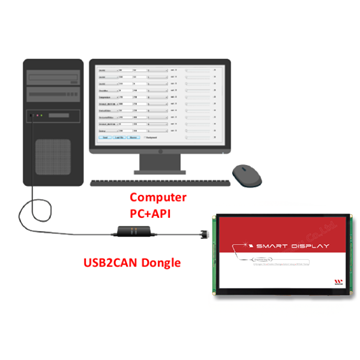

Why Choose WINSTAR for Display Bonding?

Through its partnership with WINSTAR, FIRST Components provides access to both Air Bonding and Optical Bonding technologies fully in-house, enabling unmatched flexibility and quality control for your projects. By choosing us, you benefit from:

• In-House Bonding Capabilities: Full control over both air and optical bonding processes ensures consistent quality, shorter lead times, and faster

response to design changes.

• Strong Technical Support: FIRST Components works closely with WINSTAR engineering teams to support customers from concept to mass production

with expert guidance for custom bonding solutions.

• Extensive Product Range:

⋄ TFT LCD modules: standard product sizes range from 0.96” to 15.6”, with custom options up to 32” available.

⋄ OLED modules: available from 1.54” to 5.5”.

⋄ WINSTAR offers a broad selection of standard products with no NRE required, while also supporting full customization to meet your unique application

needs.

• Reliable Delivery & Quality: Proven production capability across Taiwan and China ensures stable supply, competitive pricing, and high-quality bonding

tailored to your application environment.

Frequently Asked Questions (FAQ)

Q1. What's the main difference between Air Bonding and Optical Bonding?

Air Bonding leaves an air gap between the cover lens and display, which can cause internal reflections, reduced contrast, and glare.

Optical Bonding fills that gap with a clear adhesive, eliminating most internal reflections and improving readability, durability, and touch performance.

Q2. Which bonding method is better for outdoor displays?

Optical Bonding is strongly recommended for outdoor or sunlight-exposed applications because it significantly enhances contrast and readability under bright

light and provides better environmental sealing.

Q3. Does Winstar support both bonding methods?

Yes. WINSTAR offers both Air Bonding and Optical Bonding in-house. This gives customers the flexibility to choose based on cost, performance needs, and

application environment.

Q4. Is Optical Bonding suitable for small displays (e.g. compact TFT or OLED)?

Yes. Optical Bonding can be applied to compact TFT LCD and OLED modules, and WINSTAR’s process ensures precision even on small sizes, without

compromising quality.

Conclusion

Choosing between Air Bonding and Optical Bonding depends on your application requirements. For indoor, cost-sensitive, or easily maintainable devices, Air Bonding is often sufficient. For rugged, outdoor, or high-performance displays that demand high contrast, durability, and sunlight readability, Optical Bonding is the better choice.

FIRST Components supports both Air Bonding and Optical Bonding solutions, working in partnership with WINSTAR to deliver bonded display modules tailored to specific application needs.

Related Display Technologies

Integrated Black Display Technology

Improve contrast and display quality for applications requiring enhanced visual performance. 》Learn more

Touch Panel + OLED Integration Solution

An integrated approach to display, touch panel, and module design for compact and reliable systems. 》Learn more