- Register

- Log in

-

Shopping cart

(0)

You have no items in your shopping cart.

FIRST Componens Academy | TFT LCD Solutions for Ultra-Low Temperatures (–40°C)

TFT LCD Solutions for Ultra-Low Temperatures Down to –40°C

Challenges of TFT LCDs in Extreme Cold Environments

In extreme low-temperature conditions such as –40°C, TFT LCD displays often suffer from performance degradation due to sluggish liquid crystal response and changes in material properties. These issues can result in slow image response, reduced contrast, or even failure to start up properly.

Such low-temperature challenges are not limited to polar research applications. In real-world markets, they are commonly encountered in the following regions:

1. North America: Northern Canada, Alaska, and regions of the northern United States, as well as high-altitude areas that experience prolonged winter cold.

2. Europe: Nordic countries (Norway, Sweden, Finland), Iceland, and other high-latitude or alpine regions.

3. Asia: Hokkaido and other cold regions of Japan, where outdoor equipment must operate reliably during the winter.

For outdoor industrial equipment, transportation systems, energy infrastructure, and automation devices, ensuring appropriate TFT LCD operation in low-temperature environments has become a critical system design consideration.

Through display module–level heating solutions such as ITO heating film and ITO heating glass, TFT LCD operation in extreme cold environments can be effectively supported, addressing startup behavior, response performance, and condensation challenges in outdoor and industrial applications.

Figure 1. Heater OFF / Heater ON Comparison at –40°C

At –40°C, TFT LCD modules without heating are prone to fogging and condensation, resulting in blurred images. When an ITO heating solution is activated, the display surface temperature increases effectively, reducing condensation and maintaining clear visibility.

Low-Temperature Limitations of Industrial TFT LCDs

Most industrial-grade TFT LCD displays are specified with a standard operating temperature range down to approximately –20°C to –30°C. When ambient temperatures fall below this range, the following issues may occur:

1. Significantly reduced liquid crystal response speed

2. Image persistence and display latency

For applications requiring long-term operation at –30°C or even –40°C, standard display modules alone may not meet application requirements. Additional heating designs are therefore necessary to keep the display module within a controllable operating temperature range.

Low-Temperature Display Solutions: TFT LCD Heating Technologies

To support TFT LCD operation in extreme cold environments, heating solutions integrated at the display module level are commonly adopted. These solutions can be categorized into three main types:

1. PET Heating Pad

2. ITO Heating Film

3. ITO Heating Glass

Each solution differs in structural configuration, optical performance, and long-term reliability, making it suitable for different display types and application scenarios.

PET Heating Pad

PET heating pads typically use copper alloy conductive materials to convert electrical current into thermal energy.

This heating method is commonly applied to TN / STN monochrome displays and is usually positioned beneath the backlight module. The generated heat is transferred through the backlight system to the liquid crystal layer, improving molecular mobility and enabling reliable startup and display operation in low-temperature environments.

Key characteristics:

1. Suitable for TN / STN monochrome displays

2. Simple structure with relatively low cost

3. Suitable for applications with limited display content

ITO Heating Film

ITO heating film is primarily used in color TFT LCD displays. Its core material, Indium Tin Oxide (ITO), provides transparent conductivity with a typical light transmittance of approximately 85%.

ITO heating film is typically integrated between the LCD panel and the cover glass. When DC voltage is applied, electrical resistance within the ITO layer generates heat, allowing the display module to maintain an appropriate operating temperature in low-temperature environments without significantly affecting brightness or image quality.

This solution helps to:

1. Improve low-temperature startup behavior and reduce display latency.

2. Reduce the risk of fogging and condensation.

3. Enhance low-temperature display performance while maintaining optical quality.

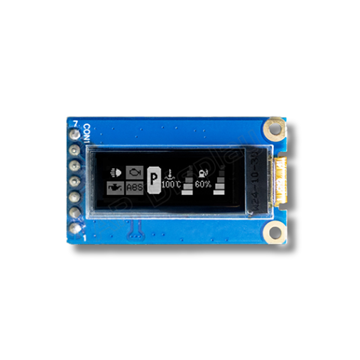

Figure 2. TFT LCD Structure with ITO Heating Film

ITO Heating Glass

ITO heating glass follows a similar structural concept to ITO heating film, with the key difference being that the ITO conductive layer is deposited directly on the glass substrate.

Compared with ITO heating film, ITO heating glass offers several advantages:

1. Higher light transmittance (approximately 90%)

2. Improved resistance to high temperatures and environmental stress

3. Superior performance in long-term reliability evaluations

This solution is particularly suitable for color TFT LCD applications that require high image quality and long-term operational reliability.

Figure 3. Functional Block Diagram of ITO Heating Glass

Anti-Fog and Anti-Condensation Performance

In cold and high-humidity environments, display surfaces are susceptible to fogging or condensation caused by temperature differentials. By integrating heating film or heating glass, the display surface temperature can be maintained above the dew point, effectively reducing condensation and ensuring clear visibility under harsh environmental conditions.

This capability is especially important for outdoor equipment operating during winter in northern and high-altitude regions of the United States, as well as Japan, Northern Europe, and cold, humid coastal areas.

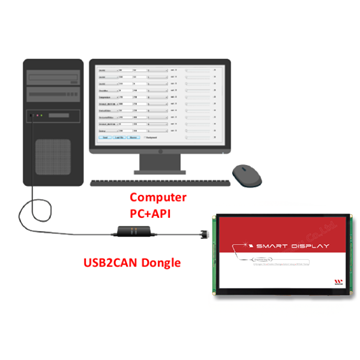

Figure 4. Anti-Fog and Anti-Condensation Performance Comparison

(ITO Heating Film vs. ITO Heating Glass)

Comparison of Heating Solutions

| Item | PET Heating Pad | ITO Heating Film | ITO Heating Glass |

|---|---|---|---|

| Thickness Impact | Low | Low | Moderate |

| Material Transmittance | Medium | Medium | High |

| Overall Module Transmittance | Medium | Low | High |

| High-Temperature Resistance | Low | Low | High |

| Long-Term Reliability | Medium | Relatively Low | High |

| Applicable Display Types | TN / STN Monochrome | Color TFT | Color TFT |

Test Data and Performance Validation

According to WINSTAR’s internal test results, under fixed voltage and standard test conditions, ITO heating film can raise the TFT display module temperature by approximately 20°C within about 240 seconds.

Consistent display performance is maintained under both ambient and low-temperature test environments.

Figure 5. Temperature Rise Curve of TFT LCD Module with Heating in Low-Temperature Conditions

Display Solutions for Global Low-Temperature Applications

Through appropriate display module heating design, the operational range of TFT LCD displays can be extended to environments as cold as –40°C.

These solutions are widely integrated in:

• Outdoor payment kiosks and ATMs

• EV charging stations

• Outdoor information display systems

• Engineering vehicles and industrial control systems

In low-temperature markets such as North America, Europe, and Japan, display heating technology continues to play an important role in improving system reliability and operational robustness as environmental requirements become increasingly demanding.

In collaboration with WINSTAR, FIRST Components provides access to TFT LCD solutions incorporating ITO heating film or heating glass, designed for reliable performance in extreme low-temperature environments. These solutions are validated for low-temperature startup, anti-fog effectiveness, and long-term operational reliability.